Quicklime

Introduction

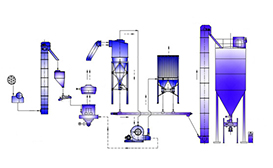

The main component of quicklime is calcium oxide,usual production method is to make natural rocks that the main component of calcium carbonate, calcined at high temperature to decompose carbon dioxide and calcium oxide(chemical formula: CaO, that is quicklime, also known as marble stone),modern use of mechanized, semi-mechanized vertical kiln and rotary kiln, boiling furnace and other equipment for production. Quicklime is a commonly used desiccant to remove water vapor by chemical absorption, especially suitable for products in steel, medicine, desiccant, puffed food, instrumentation, electronic telecommunications, leather, textile and other industries.