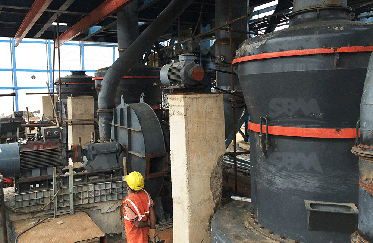

Equipment Selection

This mill has many merits that traditional grinding mills fail to own, such as cone gear’s whole transmission, inner oil absorption lubrication system, arc air flue and multinomial international advanced technologies. Besides, it owns multinomial autonomous patent technology property rights

SBM has a technical service team consisting of 25 senior engineers, 46 engineers and 165 senior technicians. On the basis of surveying the planning site for customers, we provide customers with detailed project design plans, provide reasonable equipment selection configuration, equipment list and project cost, design site basic drawings, and design special processes according to customer's special requirements. The team's expertise covers the entire process chain of limestone milling.

| Equipment | Investment | Energy consumption | Land occupation | Maintenance |

| Ball mill | High | High | Large | High cost |

| Traditional Raymond mill | High | High | Large | High cost |

| European Mill System | Low | Low | Small | Low cost |