Phosphate ash is often divided into:

Flufluorophosphate ash 3Ca3 (PO4) 2CaF2, molecular weight: 294;

Fluorophosphate 3Ca3 (PO4) 2CaF2, molecular weight: 388;

Chlorpyrifos 3Ca3 (PO4) 2CaCl2, molecular weight: 421;

Hydroxiphosphate ca5 (PO4) 3OH, molecular weight 346;

Carbon phosphorite Ca10 (PO4) 6 (CO3), molecular weight 1030;

There are two types of open pit and underground mining. Open-pit mining of shallow lysing phosphorus ore is the most important method at present. Due to the successful use of large mining machinery, the cost of stripping the mulch or mining the phosphorus ore layer is low. For some solid ore bodies, it can be loosened by blasting method and then shoveled.

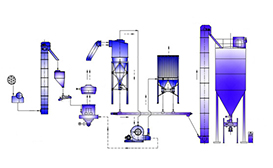

The extracted original ore is transported (with tools or pipes) to the nearest processing plant for enrichment. Some buried deep, covering the amount of stripping too large phosphorus ore, then the use of underground mining, commonly used is the housing column method. The goal of phosphorus mineral enrichment is to minimize the separation and removal of impurity minerals and improve the grade and quality of phosphorus ore. The enrichment process includes the following unit operations:

(1) Crushing and grinding

Reducing the particle size of ore, so that phosphorus minerals and impurity minerals dissociated, phosphorus minerals and impurity minerals in phosphate ore often bond together to varying degrees, only grinding to a certain degree of granularity, can be dissociated, the degree of grinding is determined by the particle size of phosphorus minerals and impurity minerals. This operation is often a basic step in the enrichment of phosphorus ore.

(2) Washing

Used to separate fine particles such as phosphorous mud, clay ore and fine-grained quartz. Since wet ore mud is often adhered to the phosphorus ore, sometimes the formation of mud clumps, to use scrubbing method to disperse it, before separation. Washing can also remove some soluble substances, such as sodium chloride and free lime in calcination phosphorus ore.

(3) Classifying

It is often graded after crushing and washing. Commongrad equipment sieves, hydraulic cyclones and spiral graders are commonly used.