1. Open flow high-fine grinding process

The open-flow high-fine grinding process is one of the grinding methods often used in fly ash processing because of its low investment and simple process. Although this process is simple, it is conducive to operation and saves production investment, but it is easy to cause over-grinding to cause serious damage to the original shape of most of the microbeads, increase the water demand, or the actual grinding of the product is insufficient, and the swimsuit is running rough, and the power consumption is also Larger.

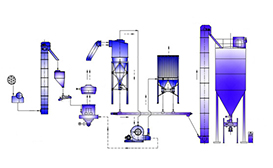

2, closed circuit grinding process

The raw ash of fly ash is fed from the head of the tube mill, discharged from the end of the mill, sent to the classifier for analysis by the hoist, and the unqualified coarse particles enter the grinding head for grinding, and the qualified finished fine materials are put into the finished product. Library.

3, semi-finish grinding process

The process can maintain the inherent particle shape of the fly ash as much as possible, can reduce the over-grinding, the secondary sorting can effectively control the fineness of the finished product, the grinding efficiency is high, and the power consumption is low. However, it is not suitable for fly ash with a large particle size and a small amount of qualified fine powder in the principle.

4. Open flow fine powder grinding process

The process is developed according to the characteristics of different fly ash and the performance requirements of the product. The process uses the open-flow method to grind the coarse powder after the sorting, and the fine powder sorted by the grinding material and the fine powder sorted before the grinding meet at the grinding tail discharge port. For the finished product. It can be divided into two processes: first sorting and then open flow grinding or direct open grinding.

First sorting and re-opening grinding is suitable for dry row or dried wet fly ash. This process retains the advantages of the above process and also greatly compensates for the amount of water under the product support. And the lack of fineness control.