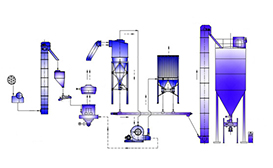

The whole machine structure is composed of main machine (Raymond mill), analysis machine, pipeline device, blower, jaw crusher, bucket elevator, silo, electromagnetic vibrating feeder, power distribution cabinet and so on. Machine working process: After the bulk material is crushed to the required particle size by the jaw crusher, the material is sent to the silo by the hoist, and then the material is evenly and quantitatively fed into the main machine grinding chamber through the vibrating feeder for grinding. The powder after grinding is taken away by the fan airflow, and classified by the analyzer. The fine powder conforms to the fine airflow into the large cyclone collector, and is separated and collected, and then discharged through the powder discharging pipe to be the finished powder.

The airflow is then drawn into the blower by the upper return duct of the large cyclone collector. The whole airflow system of the machine is closed and circulating, and it circulates under positive and negative pressure conditions. There is a certain water content in the material to be ground in the grinding chamber. The heat generated during grinding causes the gas in the grinding chamber to evaporate and change the gas flow. At the same time, due to the tight sealing of the joints of the pipes of the whole machine, the outside air is sucked in, so that the air volume of the circulating airflow is increased. To this end, the balance of the airflow is achieved by adjusting the residual air duct between the fan and the main engine, and the excess gas is introduced into the bag filter, and the fine powder brought in by the residual gas is collected, and the remaining gas is purified and discharged.