Calcium carbonate

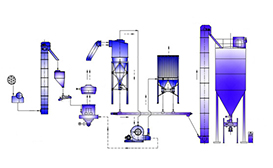

Calcium carbonate is a common inorganic compound commonly known as limestone, limestone, stone powder, etc., and is found in rocks such as vermiculite, calcite, chalk, limestone, marble, and travertine. Calcium carbonate can be classified into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate, and crystalline calcium carbonate depending on the production method. Heavy calcium carbonate (heavy calcium) is obtained by directly pulverizing natural limestone, calcite, etc. by a mechanical method (Raymond mill or the like). Light calcium carbonate (light calcium) is obtained by calcining limestone at high temperature, water digestion, carbonization of carbon dioxide, and finally dehydration, drying and pulverization.